PRODUCT

Iron containing sludge resource treatment equipment

Category:

Iron containing sludge resource treatment equipment

Message

Product Description

Product Introduction

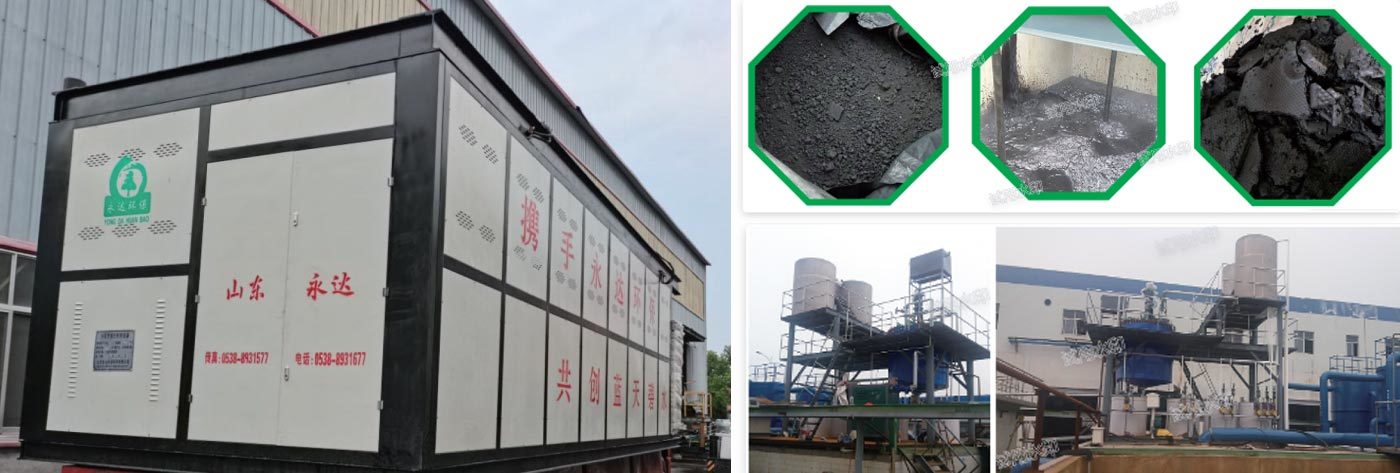

The steel industry and metal products industry require the removal of iron oxide scales on the surface of steel during the production process, and hydrochloric acid is used for pickling. During the pickling process, a large amount of acidic rinse water is generated. Acidic flushing water mainly contains free acids and iron ions. At present, most domestic enterprises adopt the neutralization method to neutralize wastewater and discharge it. However, this method consumes a large amount of lime or alkaline solution and produces a large amount of iron containing sludge with a moisture content of 99% that cannot be treated, causing serious secondary pollution and putting great environmental pressure on enterprises.

This technology is to adjust the pH value of the sludge neutralized by acid washing wastewater from steel pickling, and then enter a multiphase reactor. After a series of chemical reactions, this sludge is converted into iron oxide, which can be magnetically separated and has a total iron content of over 60%, achieving resource utilization. This not only solves environmental problems, but also turns waste into treasure, achieving the recycling and reuse of waste resources

Use.

Product Introduction

Sludge treatment is an essential step after treating sewage, mainly to remove organic matter and reduce water content in sludge, in order to reduce its impact on the environment.

Application scope

1.Wastewater treatment plant

2.Pollutant treatment

3.Urban environmental protection

4.Drying systems for household sludge, printing and dyeing, papermaking, electroplating, chemical industry, leather, and various types of sludge

Equipment characteristics

1.Green and environmentally friendly

2.Security automation

3.Energy saving and high efficiency

4.A wide range of applications

5.Save time, money, and effort

6.Durable and has a long service life

Product Name: Iron containing Sludge Resource Treatment Equipment

This technology is to adjust the pH value of the sludge neutralized by acid washing wastewater from steel pickling, and then enter a multiphase reactor. After a series of chemical reactions, this sludge is converted into iron oxide, which can be magnetically separated and has a total iron content of over 60%, achieving the goal of resource utilization. This not only solves environmental problems, but also turns waste into treasure, achieving the resource recycling and reuse of waste.

ADVANTAGE

A TEAM OF PROFESSIONALS

We invest every day in innovative production processes to guarantee you the highest quality products

WIDE PRODUCT CATALOG

You find the site constantly updated with the latest products to ensure you the best service at all times.

YASHENG HELPS YOU

We assist you at all stages of the purchasing process

FACTORY

HONOR

RELATED PRODUCTS

MESSAGE